Modern Day Slavery – Changes in the Procurement Industry

A chance for CPO’s to stand up and be counted

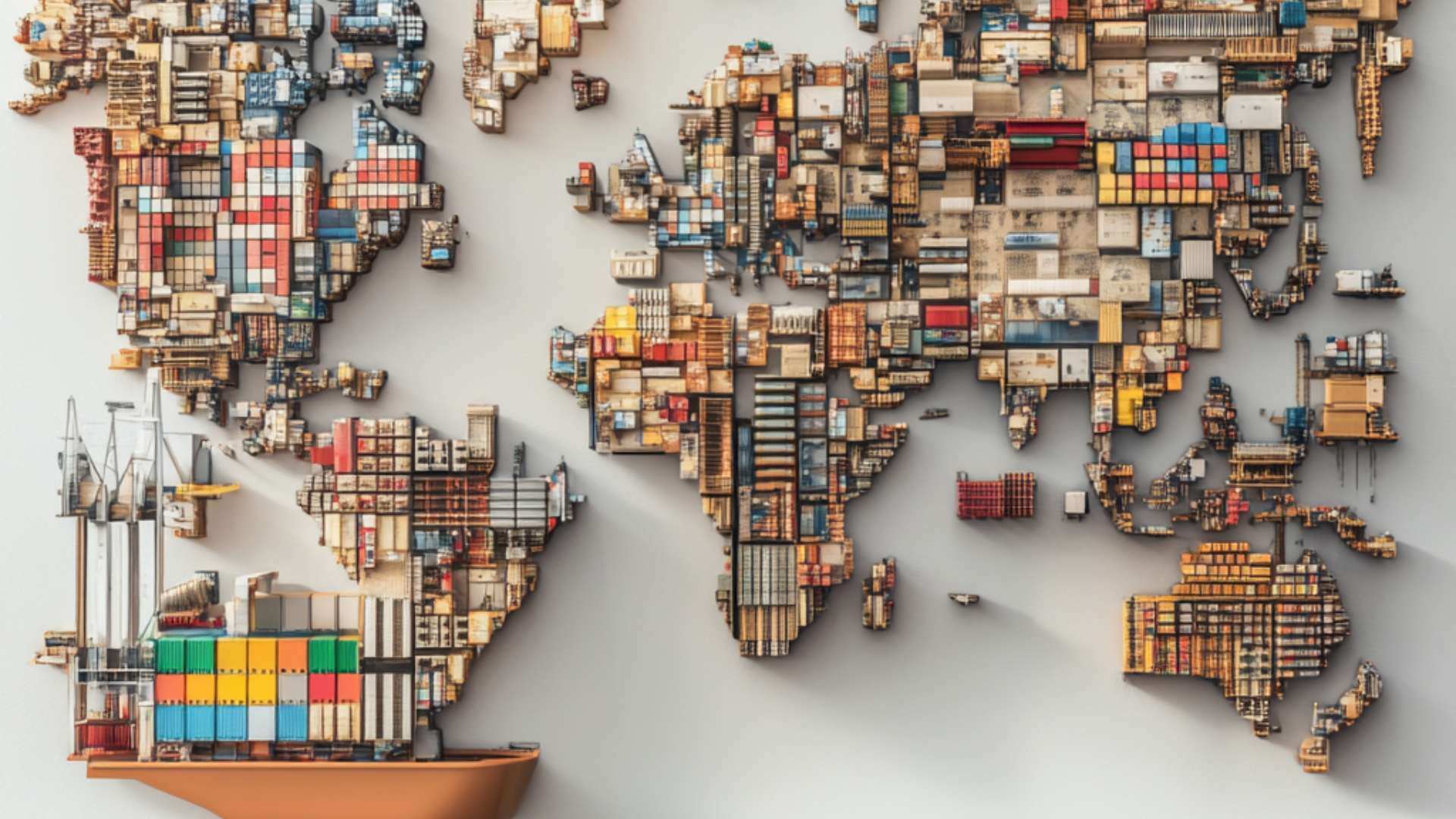

Risk management involves identifying, assessing, and controlling risks arising from operational factors and making decisions that balance risk and benefits. Within today’s procurement organization supply chain risk management is a top priority, as firms can lose millions because of supply disruption, cost increments, non-compliance penalties, and incidents that cause damage to both: the organizational brand and reputation.

What Research is Telling us

Researchers have calculated that supply chain disruption doubled in priority relative to other enterprise disruptions (approximately half of firms surveyed said they were concerned or extremely concerned about this.).

What is Classified as a Disruption

Procurement leaders define supply disruption as any unforeseen event that may disturb the normal flow of goods and materials in a supply chain. Such disruptions can have significant consequences on operations.

From a longer-term perspective, supply disruptions can negatively affect share prices and a company’s long-term balance sheet. For a purchasing organization, a supply disruption can also mean the inability to meet demand and satisfy its customers.

Supply disruptions are varied and can come from a range of sources, including physical damage at production facilities, natural disasters, strikes and labor disputes, capacity issues, inventory problems, incorrect forecasts and delays.

Risk Classification & Management

Identifying specific risks is a critical first step in any risk control process. Here are a few things we need to consider:

These risks can range from an unexpected or unfavorable change in the FX rate, or extend to the fiscal management of a supplier.

Some examples of financial risks include project and cost overruns, finding the limitation, constructive changes, and missed milestones requiring additional funding. Financial risks also encompass unexpected cost overruns that may be linked to other risk factors such as changes in the scope of work required to successfully complete the activity.

Legal and contractual risks often relate to disputes or different understanding of contractual obligations, or from not meeting the requirements within a given set of terms and conditions. Civil lawsuits, IP theft should also be considered.

In the sourcing process, it is important to evaluate the risk to the environment created by a given supplier or contractor. Environmental risk includes the organization’s impact on natural resources such as: water, air, and soil as a result of discharges, emissions, and other forms of waste.

When the corporate regulatory environment changes in response to a new government or to increasing awareness of changing social conditions, climate, etc., many institutions experience difficulty adapting. Sourcing efforts, especially those in low-cost countries, must consider the impact of these changes on the culture and business operations within that environment.

The unknown human element also poses great risk, perhaps most of all.

Often activities are placed in danger by illness or injury or due to the exit of key personnel. Sometimes, it may be the result of bad decision making by people in the forefront of the action.

In addition to these 5 key categories outlined, we should also consider the following: market factors, political climate, regulatory environment, economic circumstances, etc.

In Conclusion

Understanding supply chain risk can enable purchasing organizations to take effective immediate actions in response to risks. Risk management should form an integral part of good purchasing and supply practice. Here at RobobAI, our AI powered procurement technology provides CPOs with a fully comprehensive suite of features, allowing procurement chiefs to manage risk throughout the supply chain from an intelligent, intuitive platform.

A chance for CPO’s to stand up and be counted

In the wake of the COVID-19 pandemic, a significant shift is occurring in global manufacturing and supply chain operations.