Activate Spend Visibility to Optimize Cost Management and Mitigate Supplier Risk

AI is transforming how businesses streamline their supply chain operations to achieve greater cost savings.

2 min read

Julian Harris : Dec 18, 2024

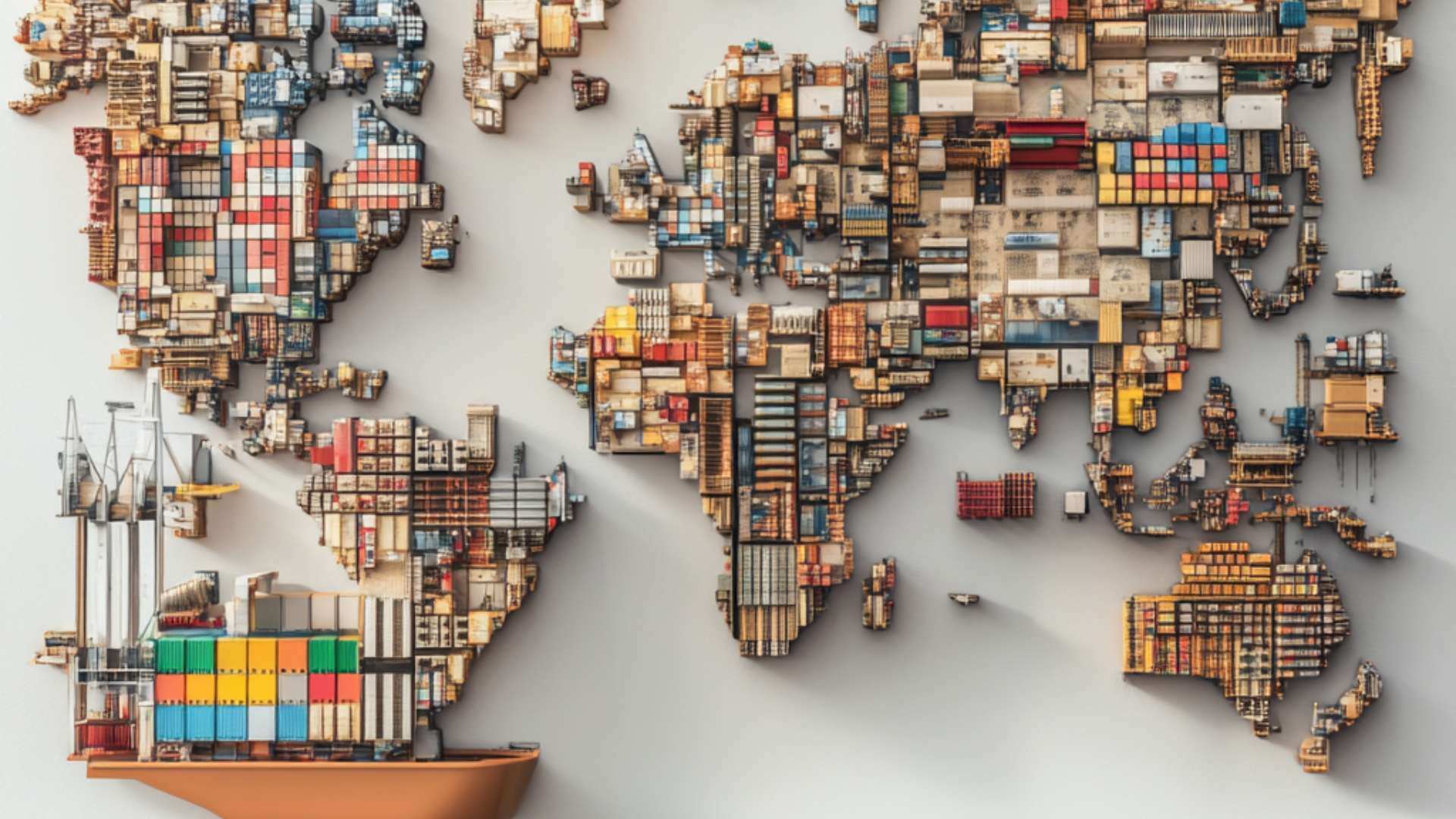

Reshoring, the practice of relocating production back to domestic markets, is gaining momentum as businesses and governments alike reassess the vulnerabilities exposed by recent global disruptions.

Julian Harris, founder and CEO of RobobAI, a fintech company specializing in AI-driven supply chain optimization, highlights several key benefits driving this trend. According to Harris, reshoring offers increased resilience against global shocks, ensuring more reliable access to essential goods during crises. The pandemic-induced shortages of medical supplies and disruptions in manufacturing networks have underscored the importance of localized production capabilities and having visibility of end to end supply chain management.

Economic advantages are another crucial factor propelling the reshoring movement. While offshoring initially promised lower labor costs, it often came with hidden expenses such as transportation, tariffs, and intellectual property risks. By bringing production closer to home, companies can streamline logistics, reduce lead times, and maintain better quality control. Additionally, localized manufacturing stimulates job creation and fosters innovation, contributing to long-term economic growth in domestic markets.

Sustainability is becoming an increasingly important consideration for businesses worldwide. Harris notes that shorter supply chains generally translate into reduced carbon emissions associated with transportation, thereby mitigating the environmental impact of manufacturing activities. The closer proximity to consumers also allows for more efficient use of resources and facilitates the adoption of eco-friendly practices, aligning with growing global demands for sustainable business operations.

Security concerns are also driving the reshoring trend, particularly in strategic sectors such as defense, healthcare, and technology. Western governments are increasingly wary of relying on foreign suppliers, especially in light of geopolitical tensions. The desire to safeguard sensitive technologies and intellectual property has spurred efforts to repatriate key industries, reducing dependencies on potential rivals.

RobobAI, Harris’s company, is at the forefront of this transition, leveraging AI technology to assist global enterprises in onshoring their supply chains. The platform provides valuable insights that drive procurement, risk, and sustainability goals for domestic production. By harnessing the power of artificial intelligence, RobobAI enables businesses to navigate the complexities of reshoring and optimize their supply chain operations in this new economic landscape.

The reshoring trend represents a significant shift in global economic dynamics, with far-reaching implications for businesses, governments, and consumers alike. As companies continue to prioritize resilience, sustainability, and security in their operations, the movement towards localized production is likely to gain further momentum. This shift has the potential to reshape industry landscapes, influence trade policies, and redefine competitive advantages in the global marketplace.

As the world adapts to post-pandemic realities, the reshoring trend underscores the importance of agility and adaptability in business strategies. Companies that successfully navigate this transition may find themselves better positioned to withstand future global disruptions and capitalize on the benefits of localized production. The ongoing reshaping of global supply chain management practices presents both challenges and opportunities, making it a critical area of focus for business leaders and policymakers in the years to come.

Read more here.

This article originally appeared in The Chicago News Journal. Read the source article here.

RobobAI brings unprecedented spend visibility to modern businesses. Our platform provides granular insights into organizational spend, empowering leaders to make strategic decisions and identify cost-saving opportunities across their entire operation.

AI is transforming how businesses streamline their supply chain operations to achieve greater cost savings.

Navigating the complexities of the modern supply chain requires more than traditional methods can offer. Businesses face challenges in gaining clear...