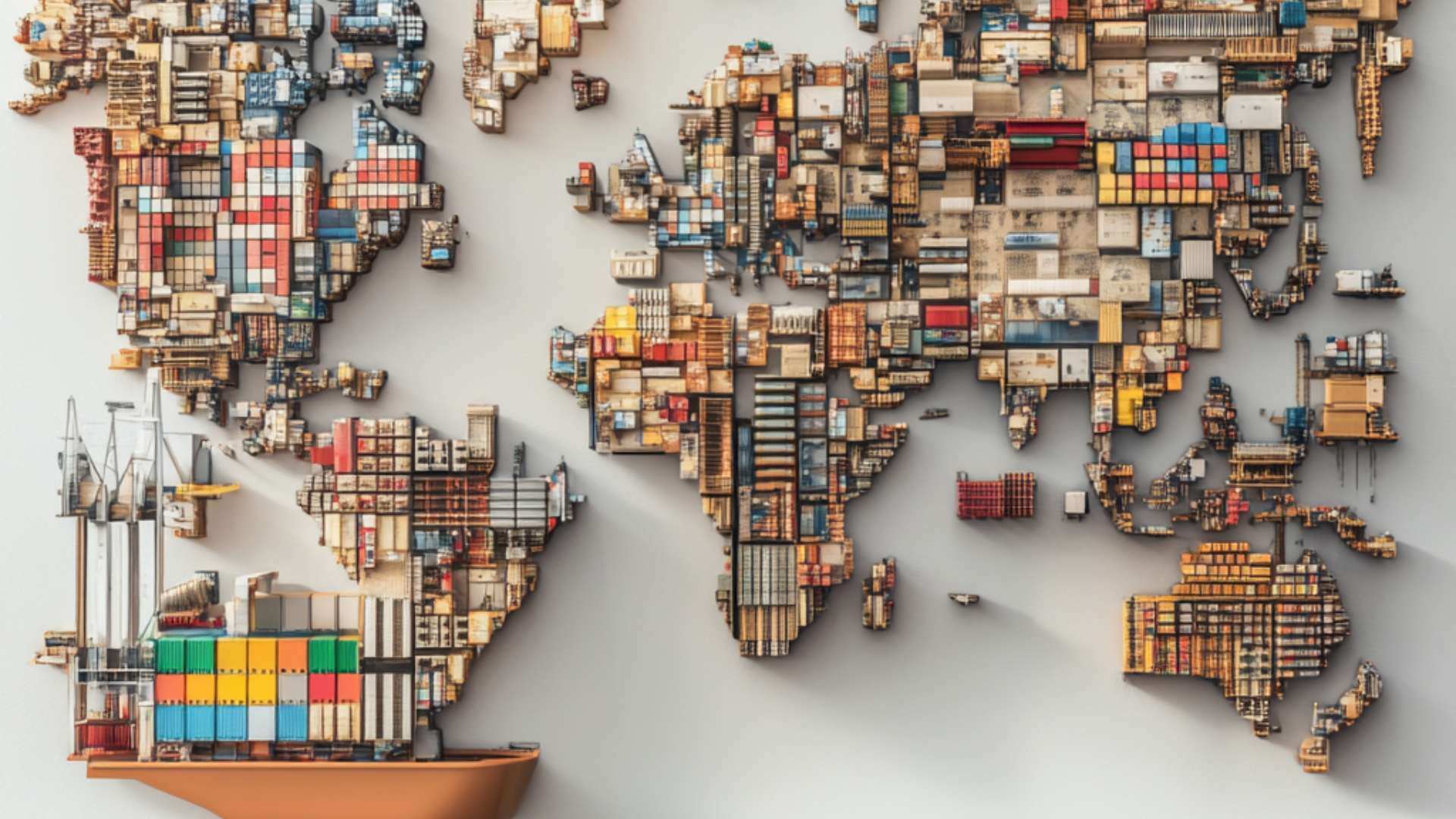

Reshoring: Transforming Global Supply Chain Management with Innovative Technology Solutions

In the wake of the COVID-19 pandemic, a significant shift is occurring in global manufacturing and supply chain operations.

3 min read

Julian Harris : Dec 4, 2024

AI is transforming how businesses streamline their supply chain operations to achieve greater cost savings.

Conventional methods hold companies back due to fragmented data, lack of holistic visibility, limited analytical capabilities.

Supply chain visibility has never been more critical as procurement leaders struggle with large volumes of disparate data and poor supply chain visibility. This makes it difficult to identify and manage cost-saving opportunities and can leave them exposed to dangerous supplier risk.

Traditional spend management methods often fall short in providing the comprehensive visibility and analytical capabilities needed to manage modern supply chains effectively.

Supply chain visibility is imperative for organizations to navigate the growing complexities of the global market.

It gives organizations the ability to identify inefficiencies and hidden opportunities within the complex cost structures of their supply chain, and it ensures that they stay proactive in their ability to manage multiple sources of supplier risk.

The function of procurement teams has evolved considerably in recent years. Constant market disruptions demand greater supply chain visibility and flexibility to respond. Organizations often need to manage their supply chain from a global scale and a detailed supplier level — simultaneously.

To achieve a clear view of their supply chain, organizations need to automate the process of consolidating large volumes of data from multiple sources, and then enrich that data by classifying it into a comprehensible format such as the universal taxonomy, UNSPSC.

Artificial intelligence (AI) is revolutionizing supply chain management by providing a 360° view of supply chain activities.

AI-powered solutions enable businesses to leverage the powerful features of machine learning and advanced analytics to provide comprehensive insights and predictive capabilities.

AI can analyze vast amounts of data from various sources, identify patterns, and predict potential disruptions before they occur. This predictive capability enables businesses to take proactive measures, mitigating risks and reducing the impact of unforeseen events.

AI also provides all the benefits of Enterprise Resource Planning (ERP) systems, consolidating data in one place for ease of visibility and analysis. Additionally, AI can help forecast demand more accurately and enhance overall decision-making processes.

Superior supply chain visibility software aggregates data from multiple sources to provide a comprehensive view of your company's supply chain.

This level of visibility and transparency is fundamental in allowing businesses to make informed decisions, streamline operations, and achieve greater cost savings.

Supply chain visibility also enables businesses to monitor supplier performance and identify potential risks early. By gaining early insights into potential issues such as unethical labor practices, cybersecurity vulnerabilities, and environmental non-compliance, businesses can take proactive measures to address these risks. This comprehensive supplier risk management approach helps maintain a stable and responsible supply chain, safeguarding the company's reputation and preventing costly disruptions.

Continuous risk monitoring is essential for understanding supplier risk, maintaining a resilient supplier base and a compliant supply chain.

Supplier risks — including cybersecurity threats, compliance issues, ethical concerns, financial stability, DE+I, and ESG risks — can pose significant reputational risks and cause disruptions in the supply chain. Continuous monitoring offers a proactive approach to managing these risks, ensuring fast detection, proactive mitigation, enhanced supplier relationships, and improved decision-making.

By adopting continuous monitoring practices, businesses can confidently navigate the complexities of supplier risk management and safeguard their supply chain integrity. This also ensures that businesses remain competitive, compliant, efficient, and uphold the highest standards of corporate responsibility. In doing so, they not only protect their operations but also build stronger, more ethical, and sustainable supply chains that can adapt to the challenges of the modern business landscape.

Implementing continuous monitoring is not just a technological upgrade; it is a strategic move that empowers businesses to stay ahead of potential risks, optimize their supply chain operations, and maintain a competitive edge in the marketplace. As supply chains continue to evolve, the importance of continuous monitoring will only grow, making it an indispensable component of effective supply chain management.

AI is transforming how businesses streamline their supply chain operations to achieve greater cost savings.

Conventional methods hold companies back due to fragmented data, lack of holistic visibility, limited analytical capabilities and ineffective supplier management. Spend analytics solutions powered by AI address these limitations by uncovering hidden insights, optimizing operations, and enabling smarter decision-making. Forward-thinking companies need to leverage the power of AI spend analytics to drive sustainable growth and achieve competitive advantage.

RobobAI’s AI-powered supply chain visibility software allows you to aggregate data and gain unparalleled insights into your spending patterns and supplier risk. Get in touch with us or book a personalized demo.

Read more here.

This article originally appeared in Supply & Demand Chain Executive. Read the source article here.

RobobAI brings unprecedented spend visibility to modern businesses. Our platform provides granular insights into organizational spend, empowering leaders to make strategic decisions and identify cost-saving opportunities across their entire operation.

In the wake of the COVID-19 pandemic, a significant shift is occurring in global manufacturing and supply chain operations.

3 Reasons You Need AI-Powered Spend Analytics. Have you modernized your spend management?